SOLO MECHATRONICS

Our Solutions

Micro Dosing / Batch Systems

You can realize reliable and high-precision automated dosing processes. Automation systems minimize deviations caused by mechanical vibrations and chemical reactions during the mixing process, ensuring repeatable and consistent results every time. These systems reduce the need for manual intervention and prevent operator errors.

Dosing systems are vital in processes where different ingredients need to be weighed and mixed in defined ratios and sequences. In recipe-based production, precise dosing of each raw material by weight directly affects the quality of the final product. In industries such as food, chemicals, pharmaceuticals and plastics, these systems maintain product standards and ensure quality continuity.

Fully automatic batch systems can be controlled by PLC and HMI interfaces, and all production steps can be monitored and managed from user-friendly screens. Recipes defined in the system can be stored in memory and past production data can be analyzed retrospectively. Thus, the production process becomes both traceable and reportable.

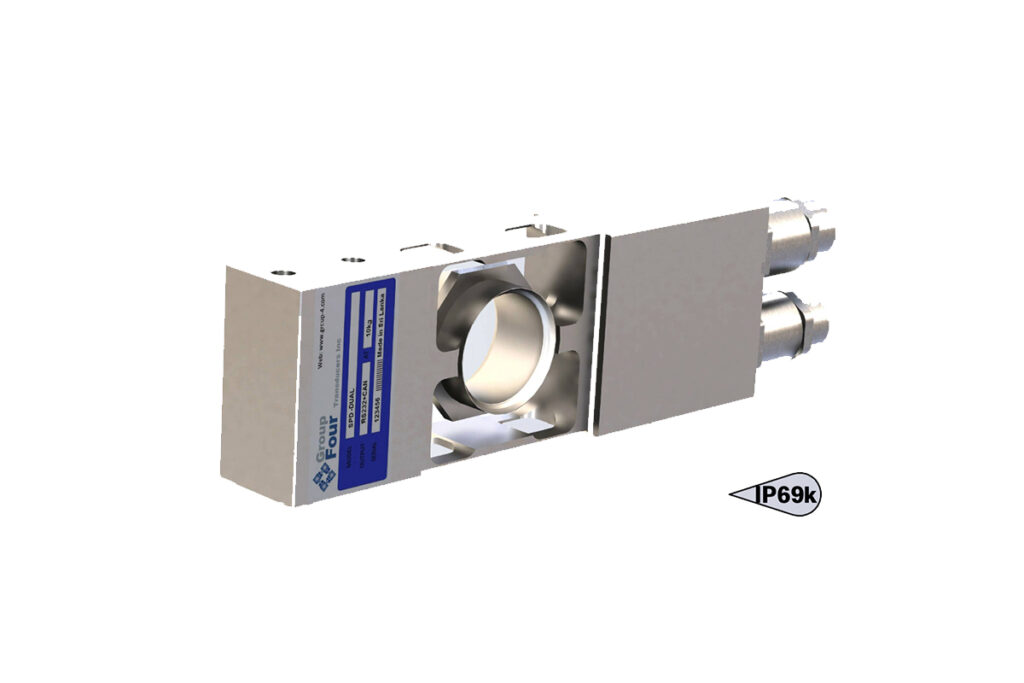

As SOLO Mekatronik, we design the most suitable dosing solutions for your process and offer complete turnkey batch applications including load cell, valve, conveyor and mixing systems. We guarantee the long life and stable operation of your systems with on-site commissioning, calibration and training support.