Quad Drum Filling System

Quad Drum Filling System

SOLO Mechatronic liquid filling machines can precisely and quickly fill all kinds of fluids (paint, thinner, solvent, oil, etc.) into containers such as cans, drums, barrels, IBCs on a weight basis, independent of variable container tare. The liquid material can be fed through a pump.

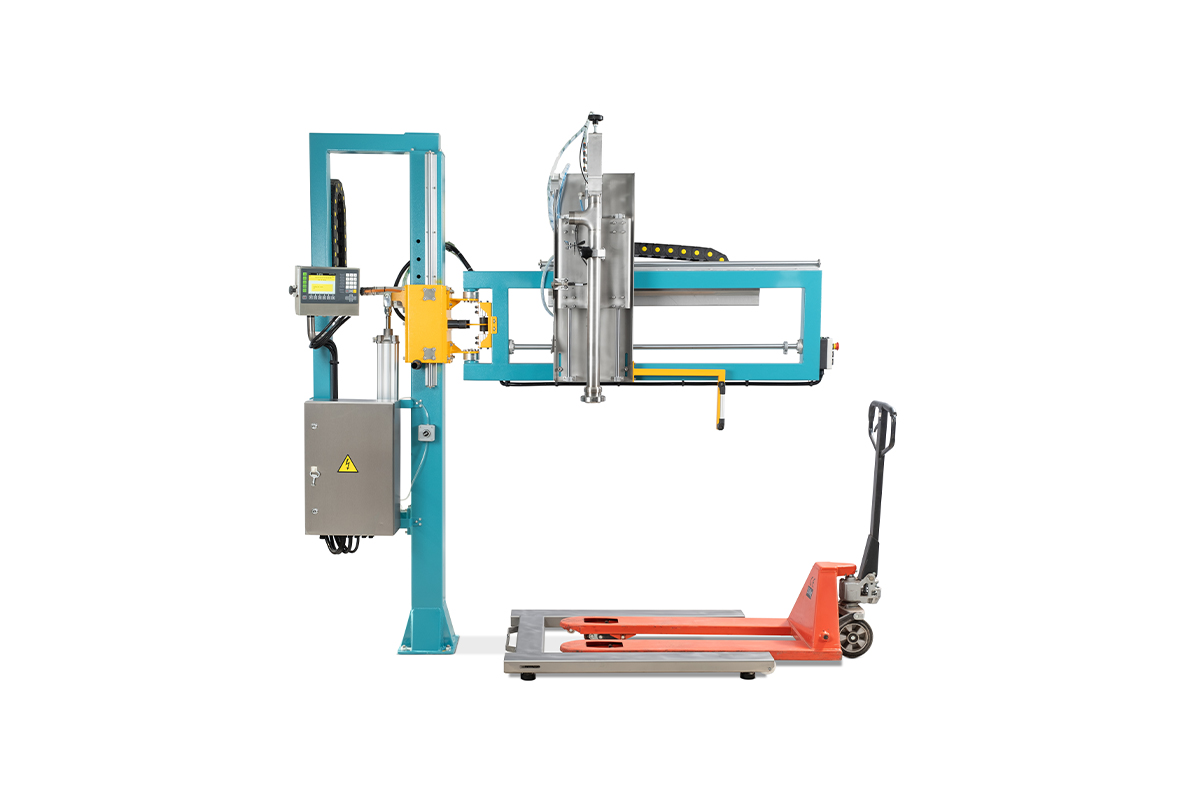

Single Barrel Filling System can be filled on the pallet, so transportation and filling operations can be done easily and in a short time. Thanks to its modular structure, it takes up little space, can be installed near the reactor or mixer in the production area and can be filled quickly and simply. Corrosion resistance and long life are ensured with high quality and high protection class selected equipment suitable for heavy industry conditions. All material contact surfaces are stainless steel, easy to remove and clean. Material specifications can be manufactured with special protection class paint, galvanized coating, teflon coating, complete stainless steel options upon request.

Marka

ÜRÜN AÇIKLAMASI

Safe, Fast and Precise Solutions for Paint, Ink and Solvent Filling

As SOLO MEKATRONİK, we are ready to meet your needs in your industrial filling processes. high precision, occupational safety and efficiency standards together. Especially paint, ink, solvent used in the filling of flammable and chemical liquids such as quadruple barrel filling systems and IBC filling solutionsoffers the ideal infrastructure for different production scenarios.

Quad Drum Filling System

It allows simultaneous filling of 4 200 liter drums placed on the pallet.

- High Precision Loadcell with weight controlled filling

- Automatic sequential filling and nozzle descent/ascent control

- Prevents foaming and overflow smart filling algorithms

- For explosive atmospheres ATEX/EX-PROOF certified Structure

- Manual, semi-automatic and fully automatic operation options

- Integrated barcode reader and prescription management options

IBC (1000 Liter) Filling System

Ideal for processes requiring large volumes of liquid transfer.

- Adjustable flow rates according to viscosity

- For foamy liquids bottom-up filling option

- Operator-assisted or fully automatic filling control

- Maximum safety with EX-proof motor and control board

- PLC controlled system structure and easy interface

Why SOLO MECHATRONICS?

- Specialized chemical resistant equipment

- Domestic production, fast spare parts and technical service support

- Easy operation with user-friendly HMI displays

- Flexible design that can be integrated with all your systems

HOW THE SYSTEM WORKS:

After the container to be filled is placed on the scale platform, the system automatically checks the tare of the container by pressing the “START” button, and if the tare is within the limits, filling starts. When the desired weight value is reached, the system switches to slow feeding. Fast and slow feeding values can be entered on the display panel. If filling is done from the bottom, the nozzle descends to the bottom, at the end of the bottom time, the nozzle rises to the middle level and parks outside the container when the filling is finished. The 2nd stage can be adjusted proportionally with the stepped pneumatic actuator. When the closing value is reached, the flow of goods is stopped, the device automatically makes the necessary adjustments in the closing value by making tolerance control. The process is repeated by placing a new container.

- High performance

- Fast and precise filling

- Easy and ergonomic operation

- Modular and space-saving design

- Over cap / under cap / dip filling options

- Non-drip, non-foaming and non-overflowing filling nozzle with homogeneous flow

- Height adjustment for different packaging types

- In-pit / above ground / wheeled U-type weighing platform options

- Precise, reliable weighing equipment

- Weighing controller with large color LCD display

STANDARD ADVANTAGES:

- User-friendly control panel with easy menu and function keys

- Target filling quantity can be changed with one button

- Possibility to work at set values with 9 prescriptions stored in memory

- Possibility to fill different containers with adjustable and changeable working height on site

- Double speed 2-stage deipten filling for precise filling without splashing, foaming or overflowing

- Functional design for easy cleaning and maintenance

- Can fill different materials in the same machine with interchangeable nozzle unit

- Two-stage Actuator and nozzle for simultaneous two-point goods flow control

Öne Çıkan Ürünler

Sorularınız mı Var?

Bize Ulaşın!

Merak ettiğiniz her konuda veya projenizle ilgili bilgi almak için bize yazın; uzman ekibimiz en kısa sürede size yardımcı olacaktır.